Import Extruder¶

Assembly¶

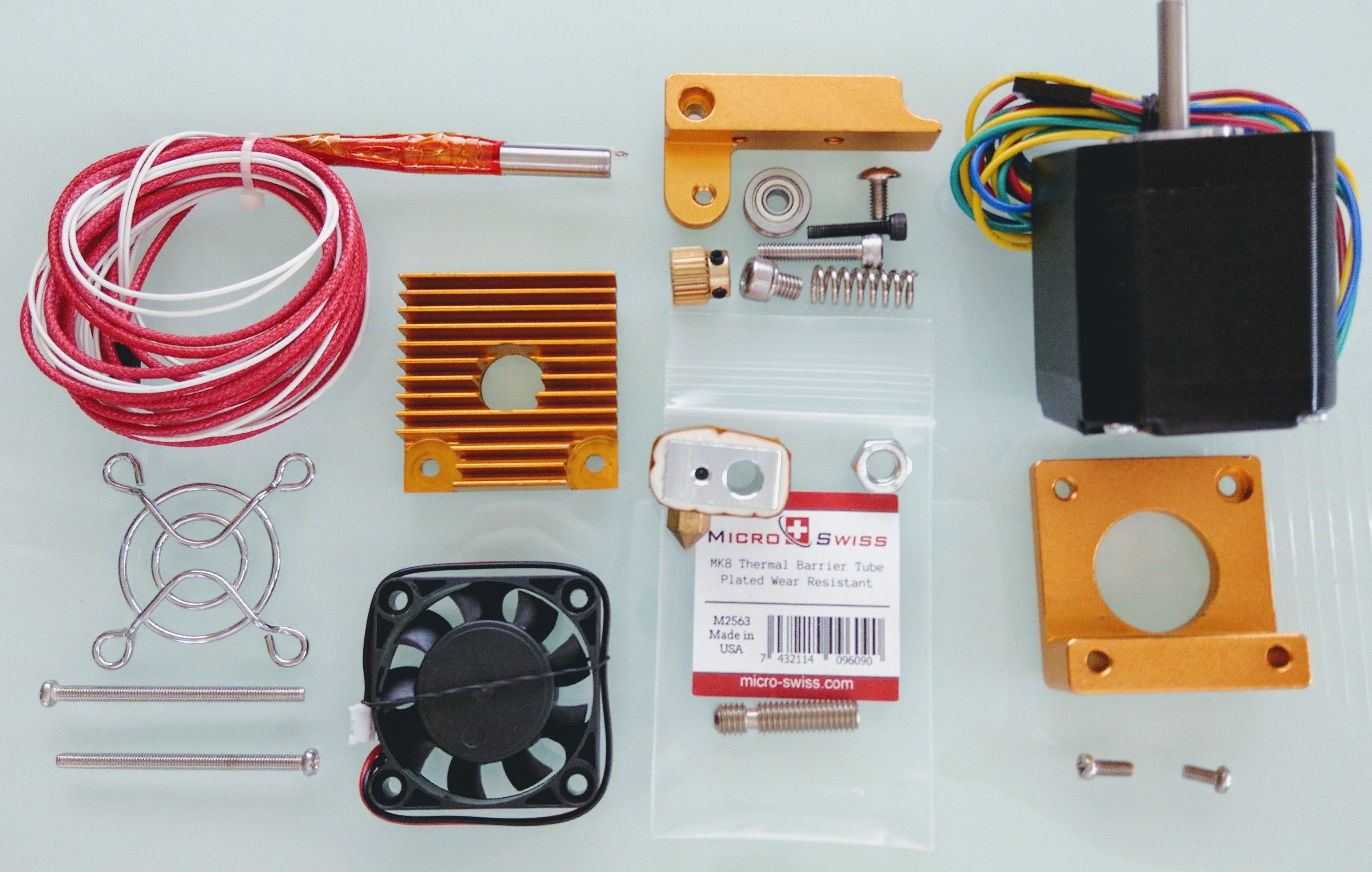

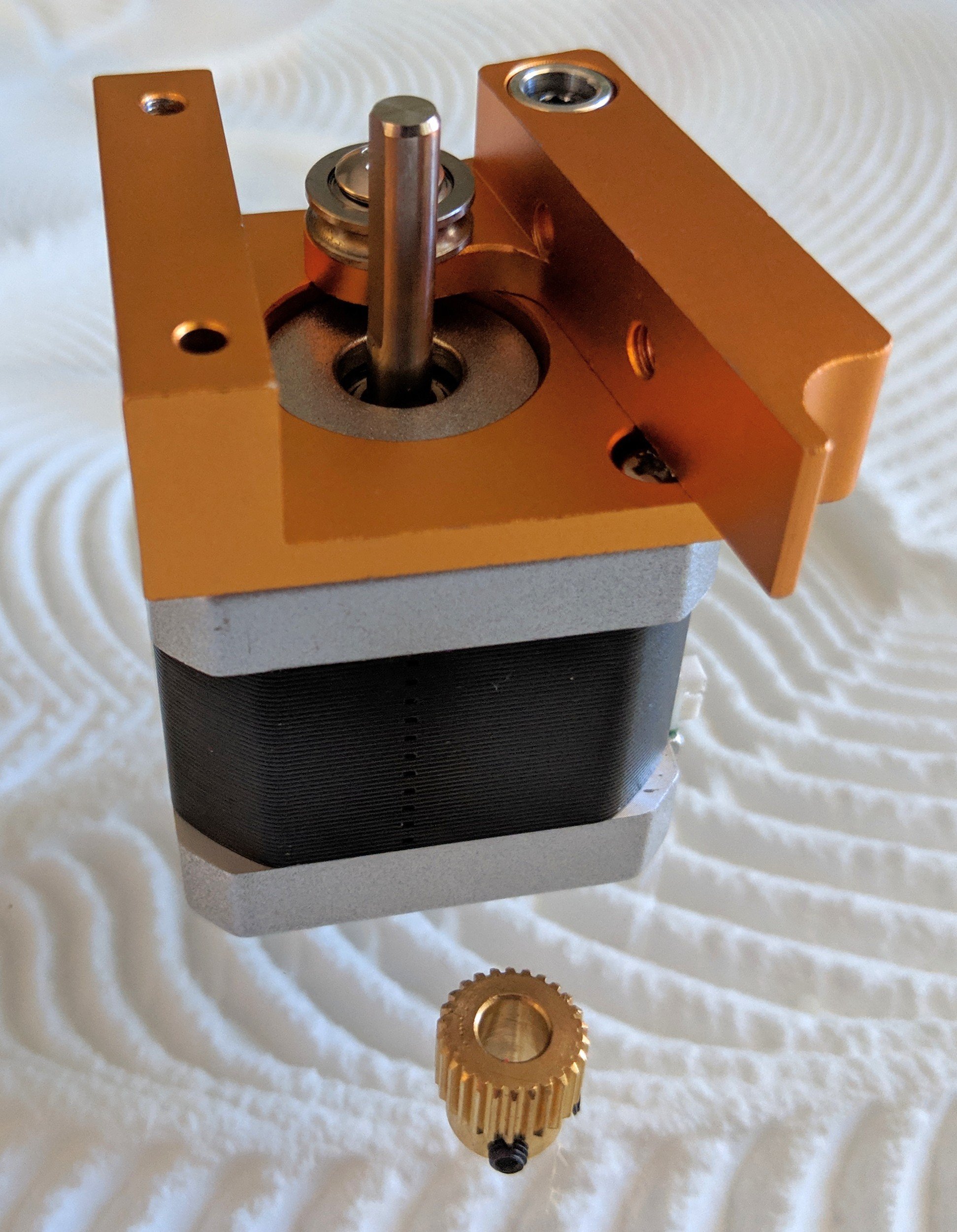

Assembly of my all metal version of the Mk8 import extruder

I ship these partially assembled. These are not assembled by me so a few extra minutes starting from scratch can save a lot of headaches in the end.

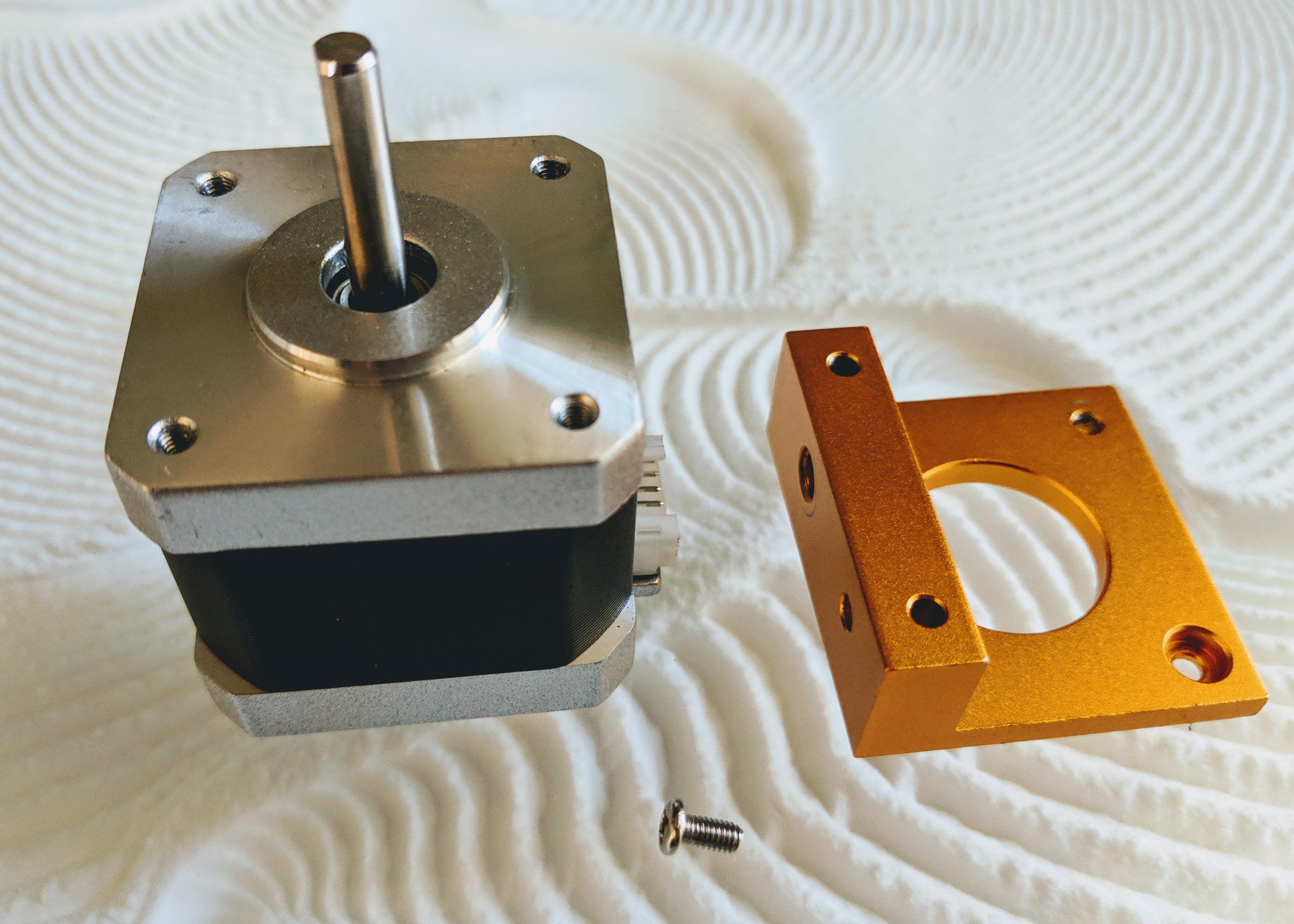

Start by screwing the base plate to the stepper with the M3x6 screw. I prefer to have the wires oriented up.

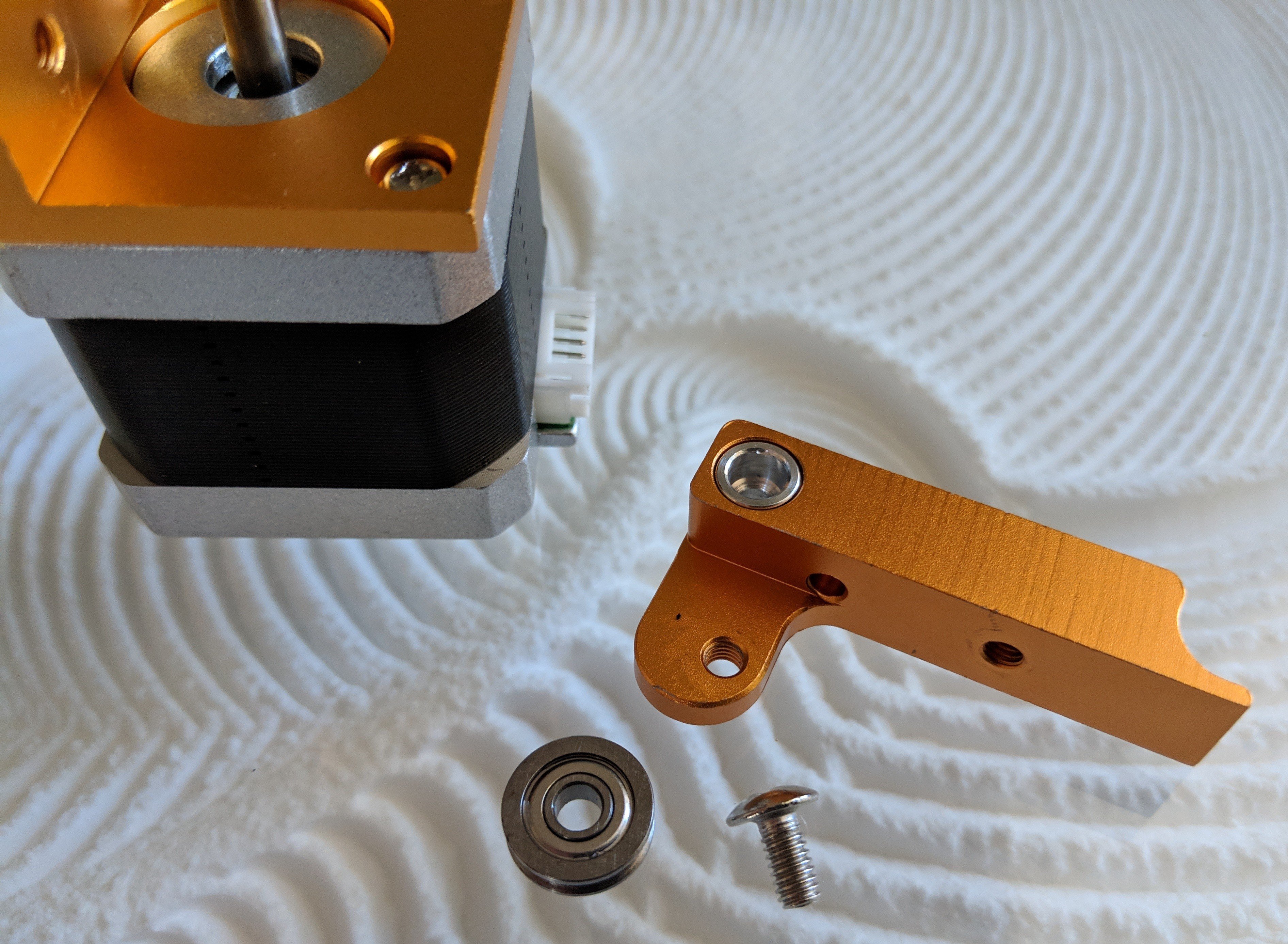

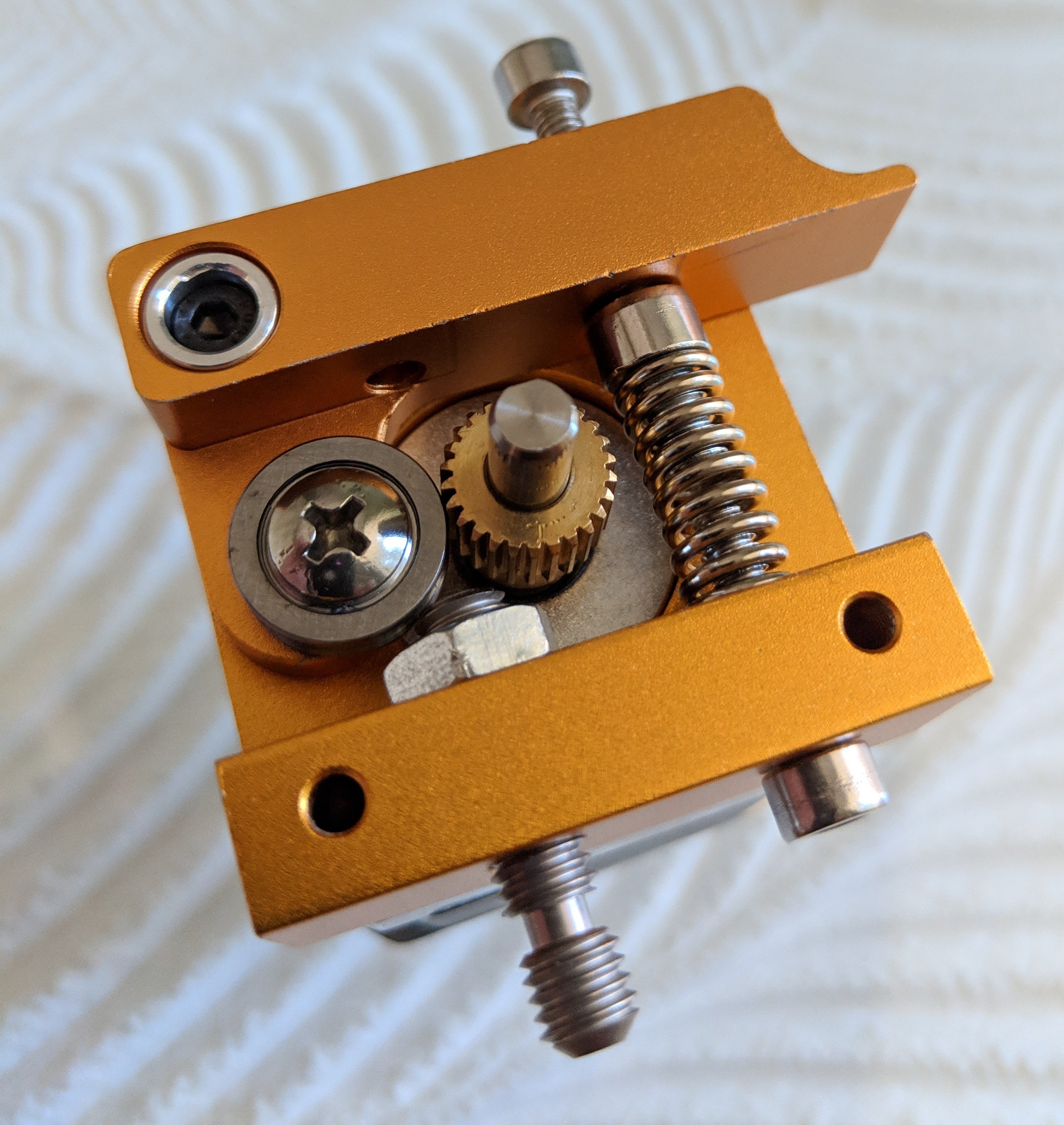

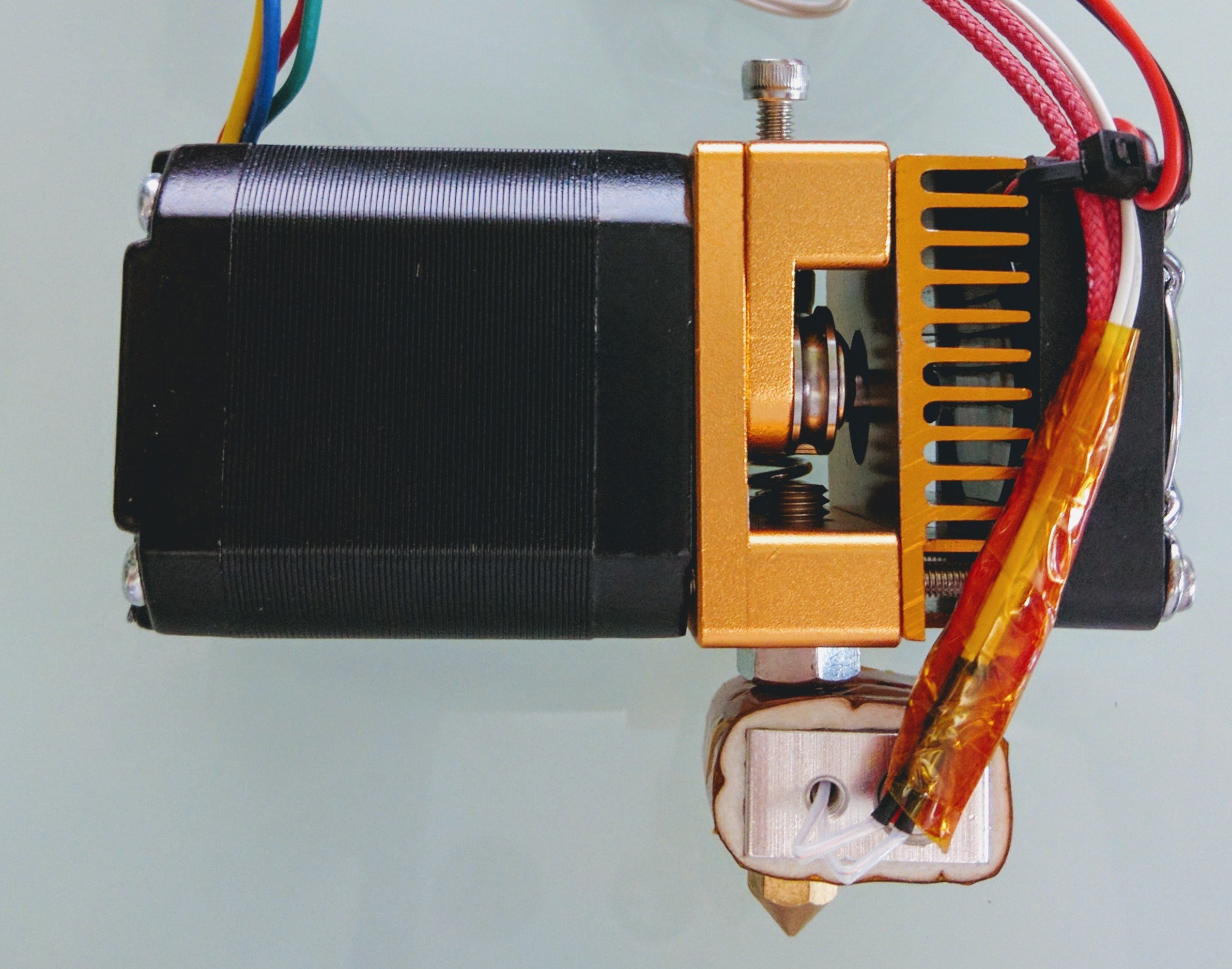

On the Tension arm add the bearing and broad headed screw. If the bearing does not spin freely, flip it over. One side is slightly offset. Make sure the bearing spins free and smoothly.

Some sets include a washer, use it if you have it. Thread locker is a good idea as well.

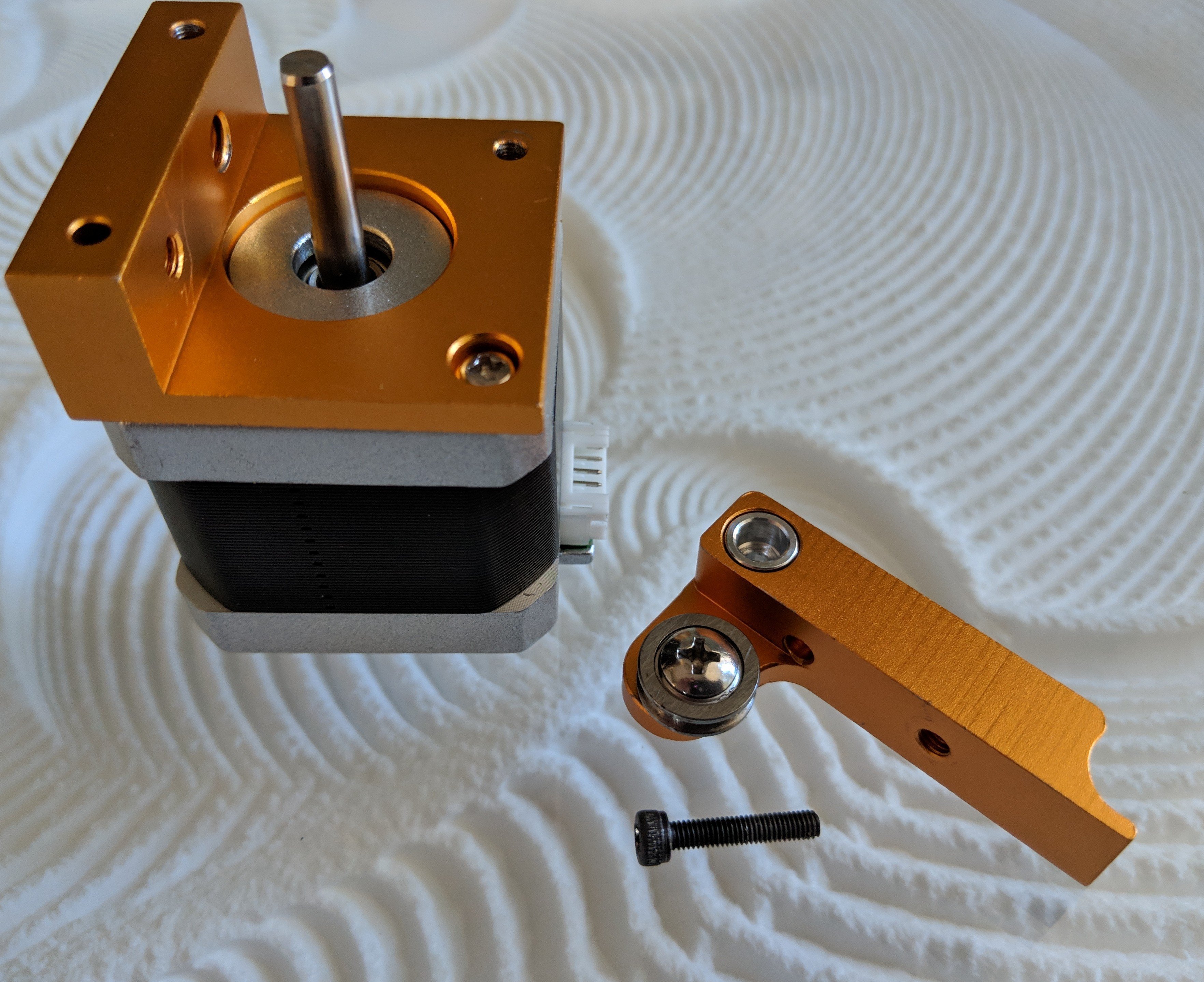

Add the tension arm and bolt. Make sure the arm swivels smoothly. If the arm binds you can loosen the screw a bit. Thread locker is a good idea here as well.

Add the pulley next. Usually the set/grub screws are positioned closer to the motor but not always. Center the teeth on the idler pulley and make certain the pulley does not hit the heat sink that gets installed later.

Tighten the set screw on the stepper’s flat spot if it has one, the second screw.

Double check the feed pulley to be sure the teeth are inline with the idler and the pulley does not hit the heat sink.

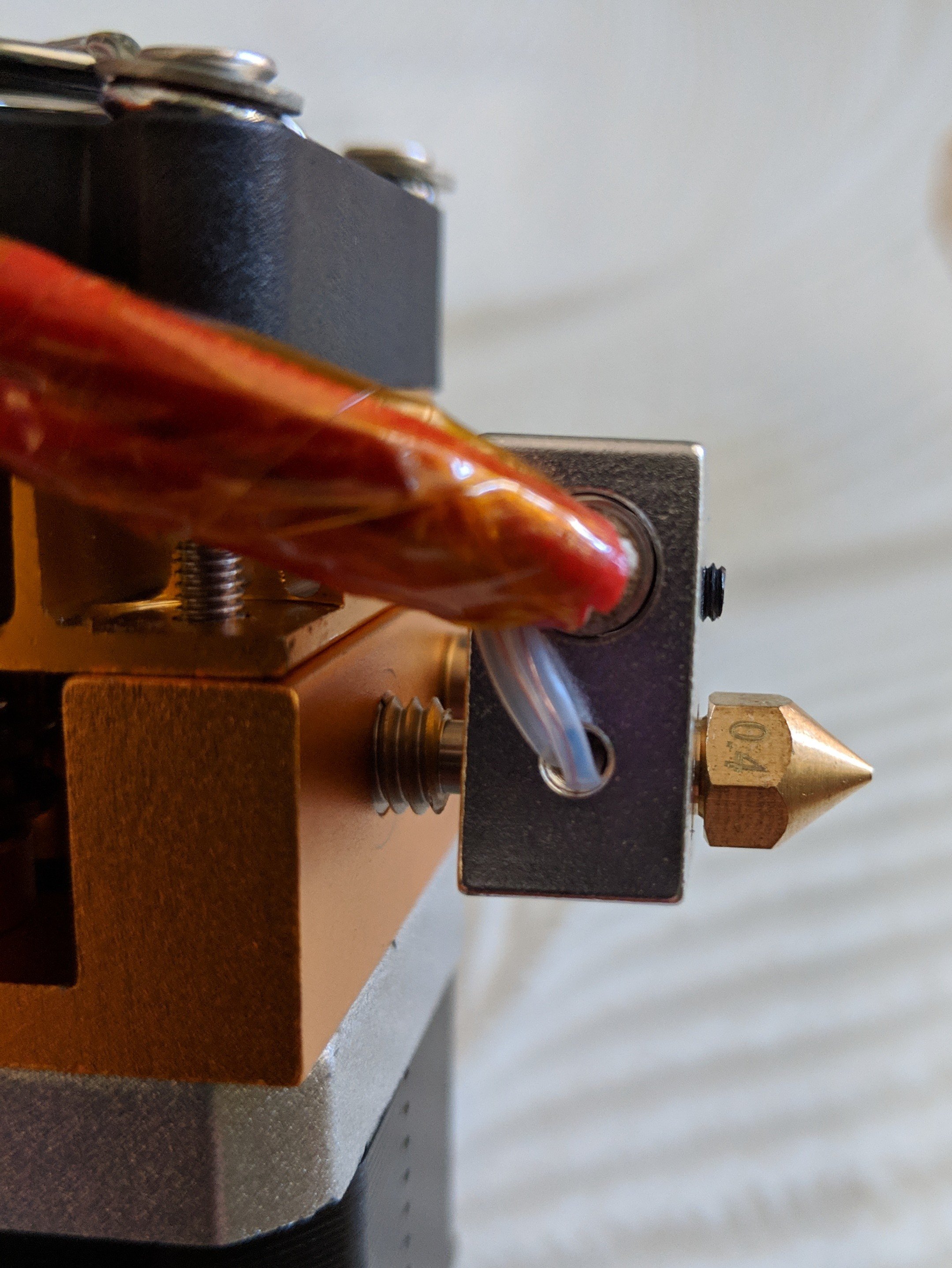

Add the MicroSwiss throat and lock nut. This throat does not contain PTFE so it can handle higher temperatures and should not need any maintenance. To help with heat dissipation the lock nut is positioned on the inside of the bracket.

Thread the throat is as far as it can go. Do not let the throat make contact with the idler or pulley. The smaller this gap the better soft and flexible filaments will print and the better the heat will dissipate from the throat when printing PLA slowly.

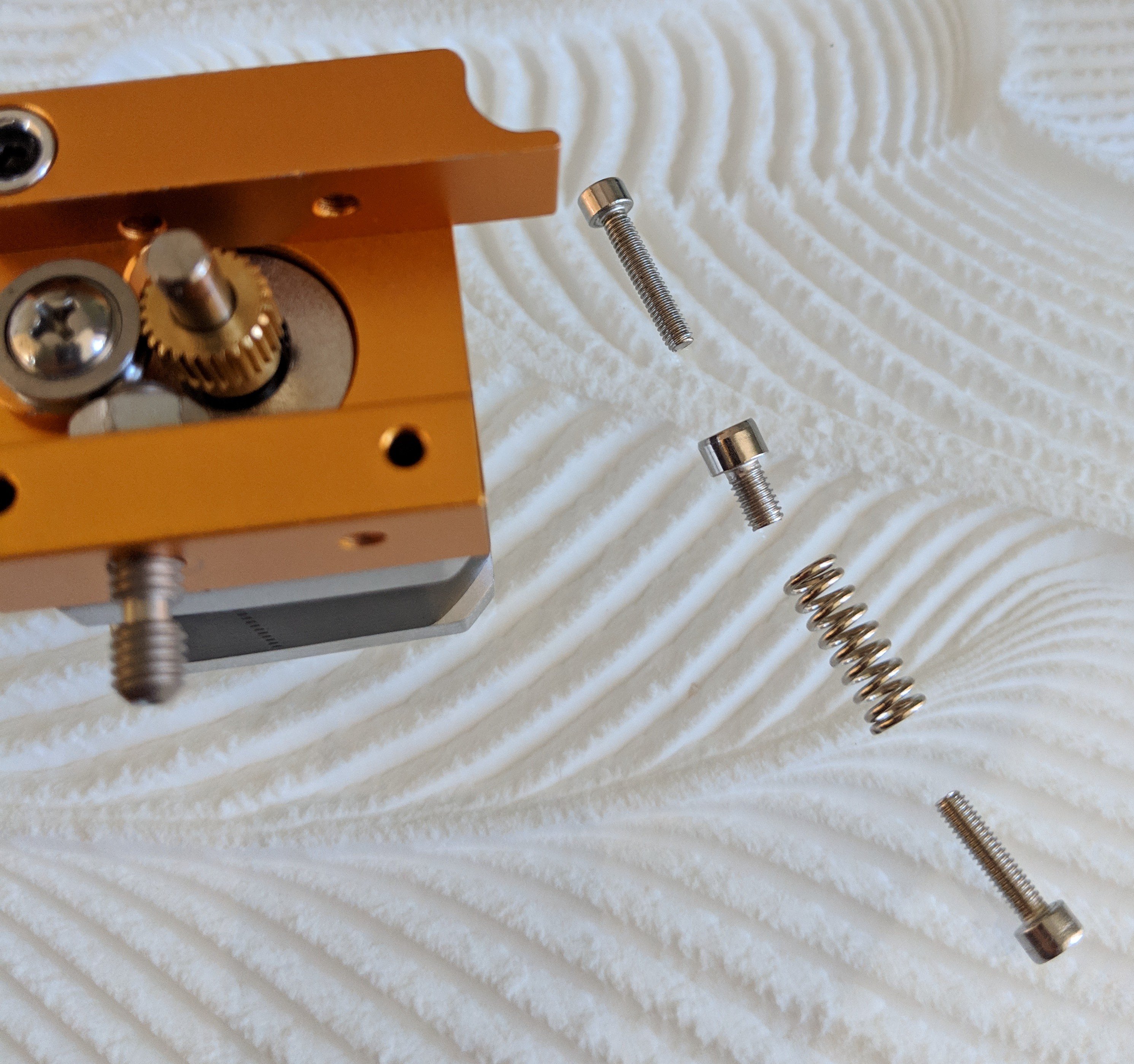

Next up is the tension stack. The bottom screw helps to retain the spring (and is not always necessary). This should be the shorter of the two screws. If this screw is too long the arm will not open enough to insert filament. If that is the case don’t use the screw or find a shorter one.

The top screw controls the filament pinch tension, tighter is not better, you want just enough to feed without slipping.

Tension stack completed. Start with little to no tension and only increase it if your filament slips.

Double check the throat is not hitting the idler or pulley.

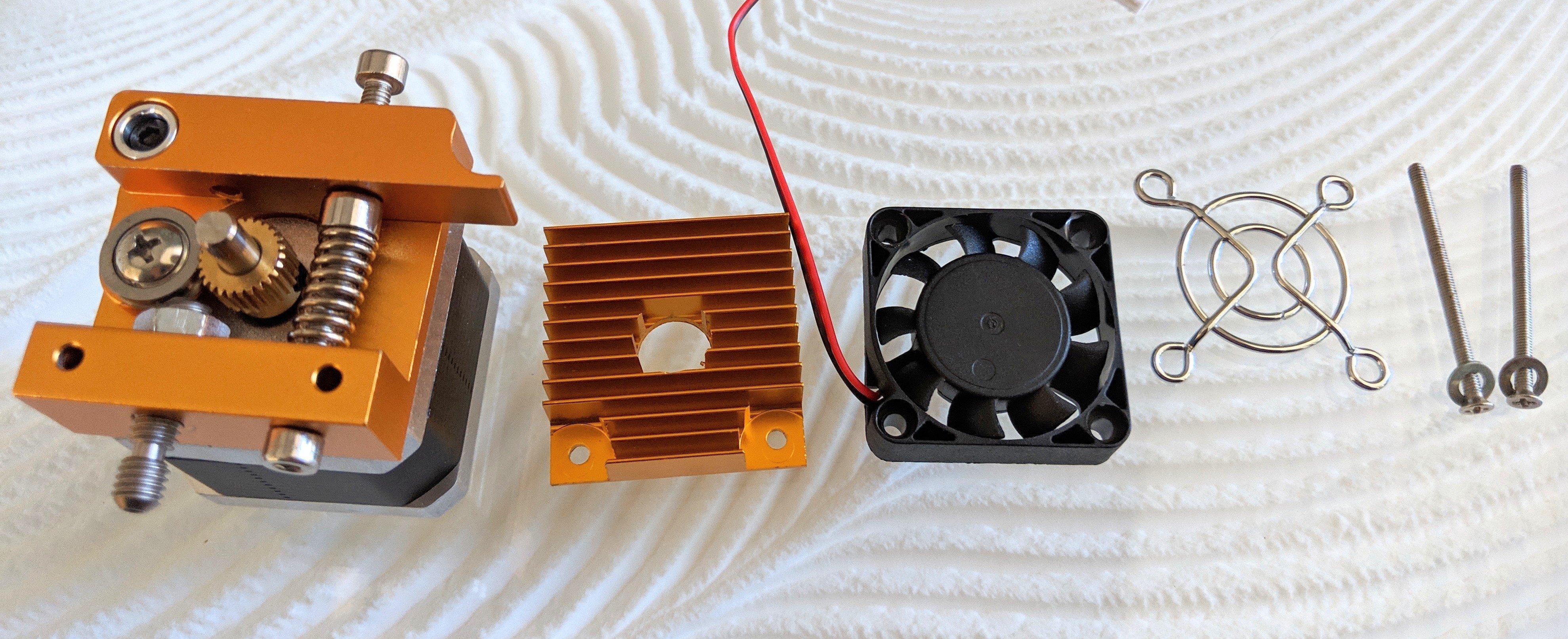

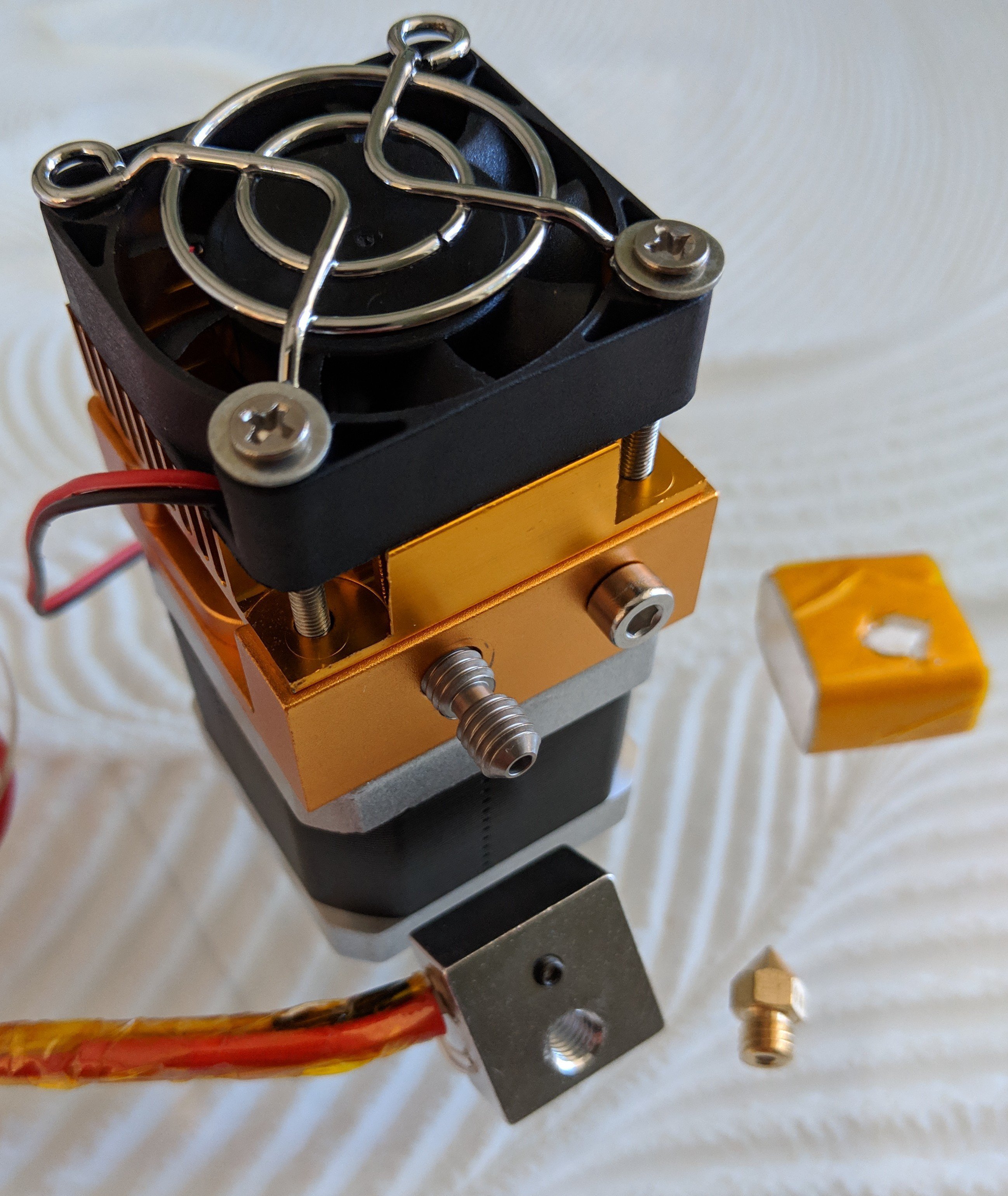

The cooling stack. the screws may or may not have washers. Position the fan wires appropriately. Tighten with moderate tension. This is where a majority of the unwanted heat gets dissipated so tension is good for heat transfer but too much will ruin the fan, so balance…

The cooling stack completed.

Warning

If your heat sink has open fins on the bottom it is best to tape off the bottom vents so the fan does not blow air on your prints only up and out.

When installing the heat block position the set screw facing down so you can change the heater without a complete tear down if necessary.

Add the heater cartridge and guide the thermistor into the small hole. Ensure it is fully inserted. Gently snug the heater cartridge set screw, careful not to damage the heater. Make sure not to move the fragile wires excessively and ensure they are not twisted and sorting out.

The nozzle is what locks the block in place. Make sure the nozzle is not locking onto the block but is instead making tight contact with the throat.

Warning

After the assembly is complete heat up the extrude to a few degrees above your intended use temp and snug up the nozzle before running any filament through.

Secure the wires to the top fan hole, and your done with assembly.

Plug it in¶

You will need power to both sides of the green plug, you can just add a short jumper wire from one side to the other. The polarity is marked on the board, double check to make sure this is correct. The fan on the heat sink needs to always run, this gets plugged directly into the green power plug, polarity matters. Extruder to port D8, polarity does not matter. Optional print fan plugs in to port D9 polarity matters.

Marlin edits¶

Very few edits required. Any firmware I release after this post will most likely already be set for this extruder by default. I will put the info here for you adventurous types.

All of these that I have gotten have used the marlin #11 thermistor, and at 32nd stepping I use 200 steps for the e value.

#define TEMP_SENSOR_0 11

#define DEFAULT_AXIS_STEPS_PER_UNIT {200,200,4535.44,200}

Even after running the PID auto tune I get a huge overshoot in temp so limiting the max current might help with this, I will update it when I get a chance to test it.

// Comment the following line to disable PID and enable bang-bang.

#define PIDTEMP

#define BANG_MAX 255 // limits current to nozzle while in bang-bang mode; 255=full current

#define PID_MAX BANG_MAX // limits current to nozzle while PID is active (see PID_FUNCTIONAL_RANGE below); 255=full current

#ifdef PIDTEMP

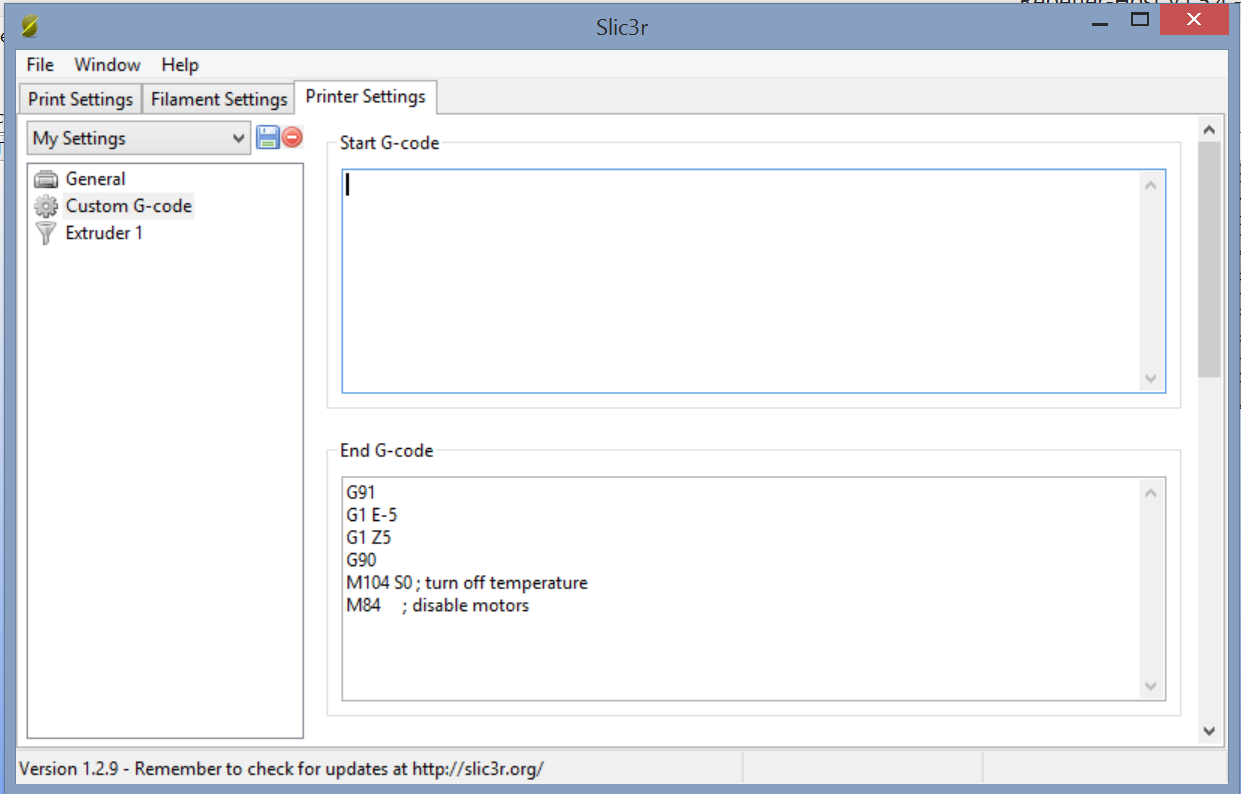

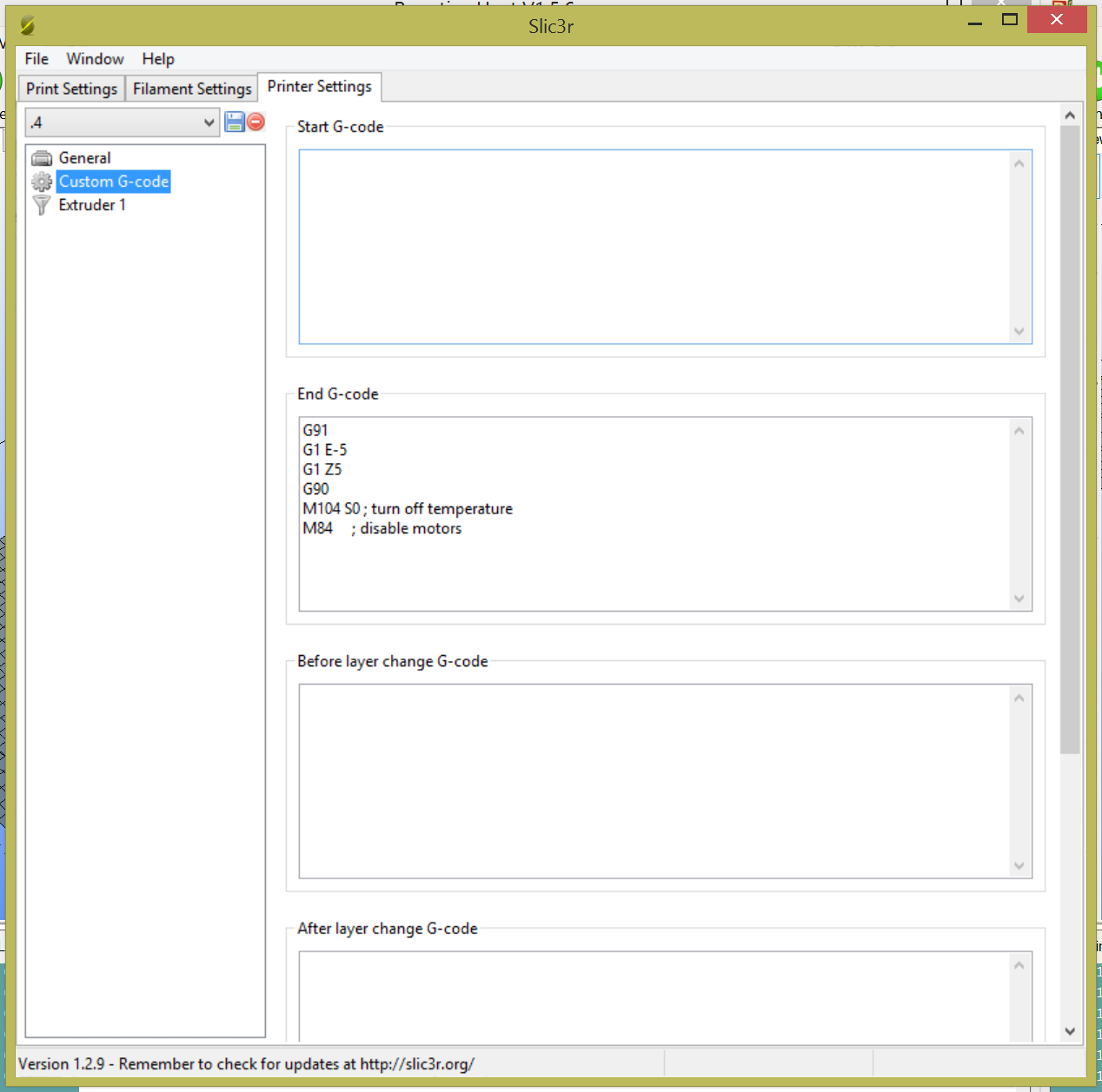

Slicer edits¶

Delete the beginning gcode, you don’t want it to home.

Change the end gcode to look like this

G91

G1 E-5 ;retract

G1 Z5 ;lift up 5mm

G90

M104 S0 ; turn off temperature

M84 ; disable motors

Not using endstops¶

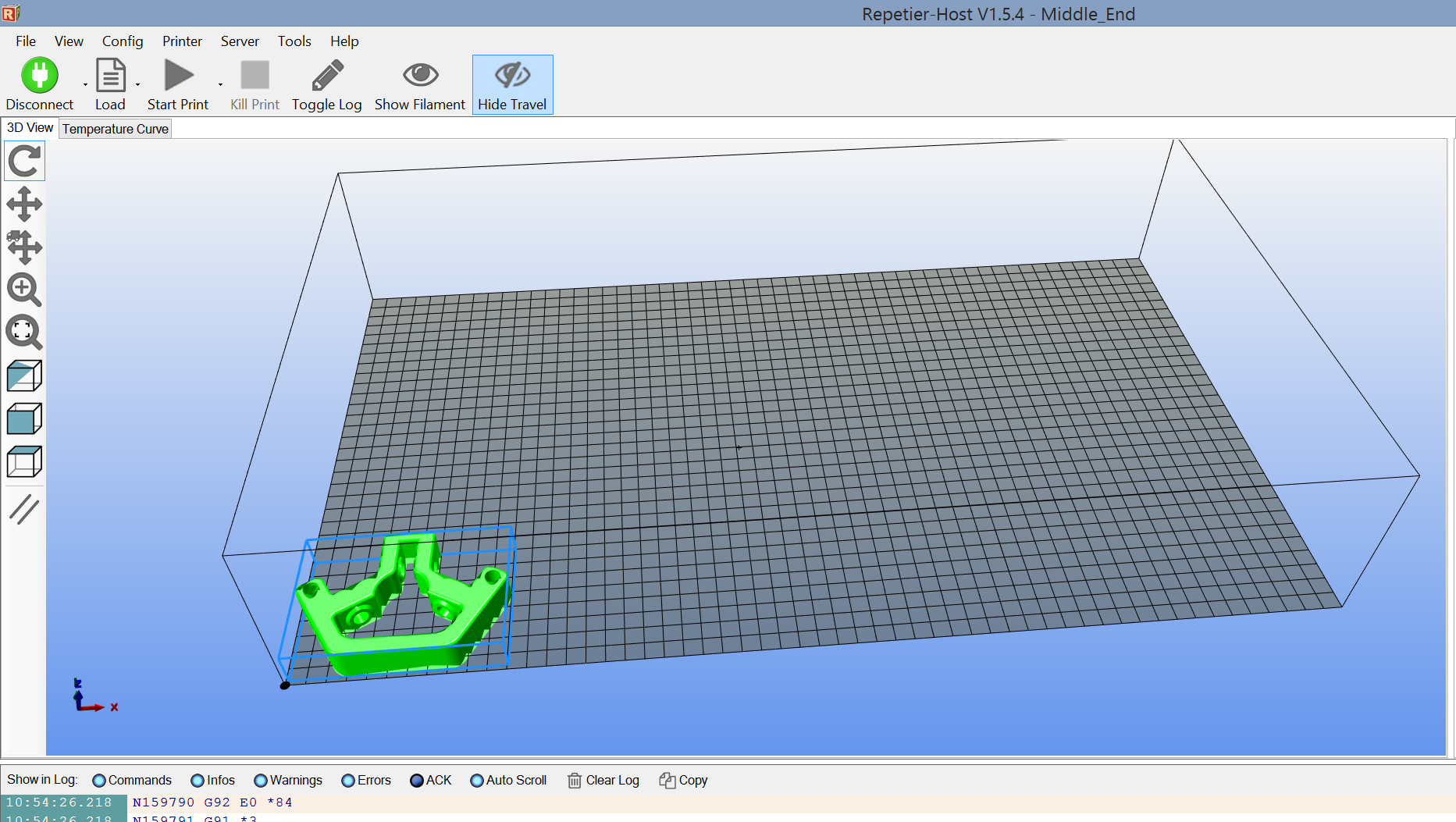

Position you parts on the lower corner (0,0,0), before you slice them. This will start your prints where ever your head is. So position the nozzle touching the bed and exactly where you want it to start. When the print begins it should lift up the correct amount and print. You can manually adjust the height during the skirt print to fine tune it.

That’s it print away. The printed parts I am shipping are starting to get printed on this cnc, and they look amazing.

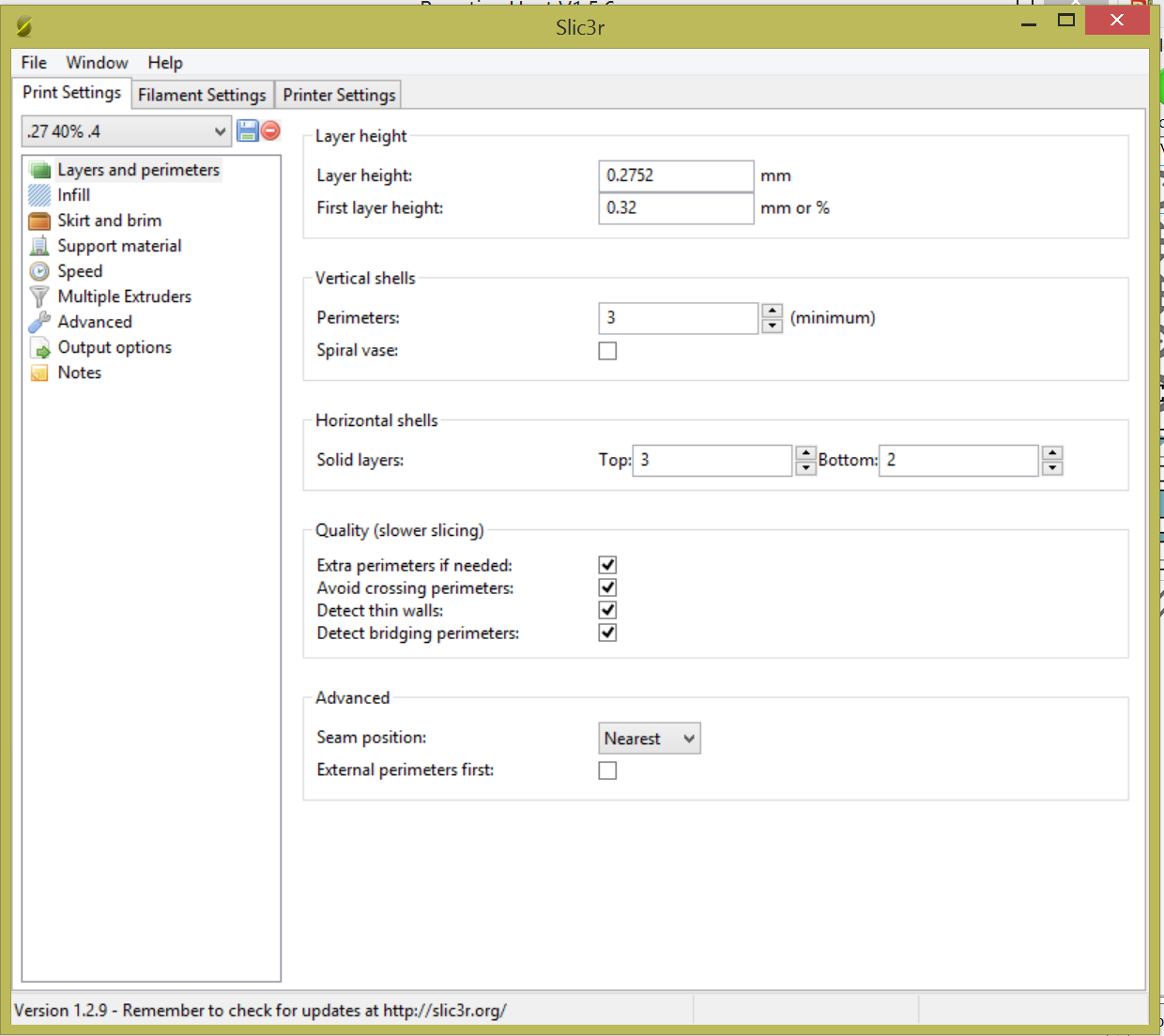

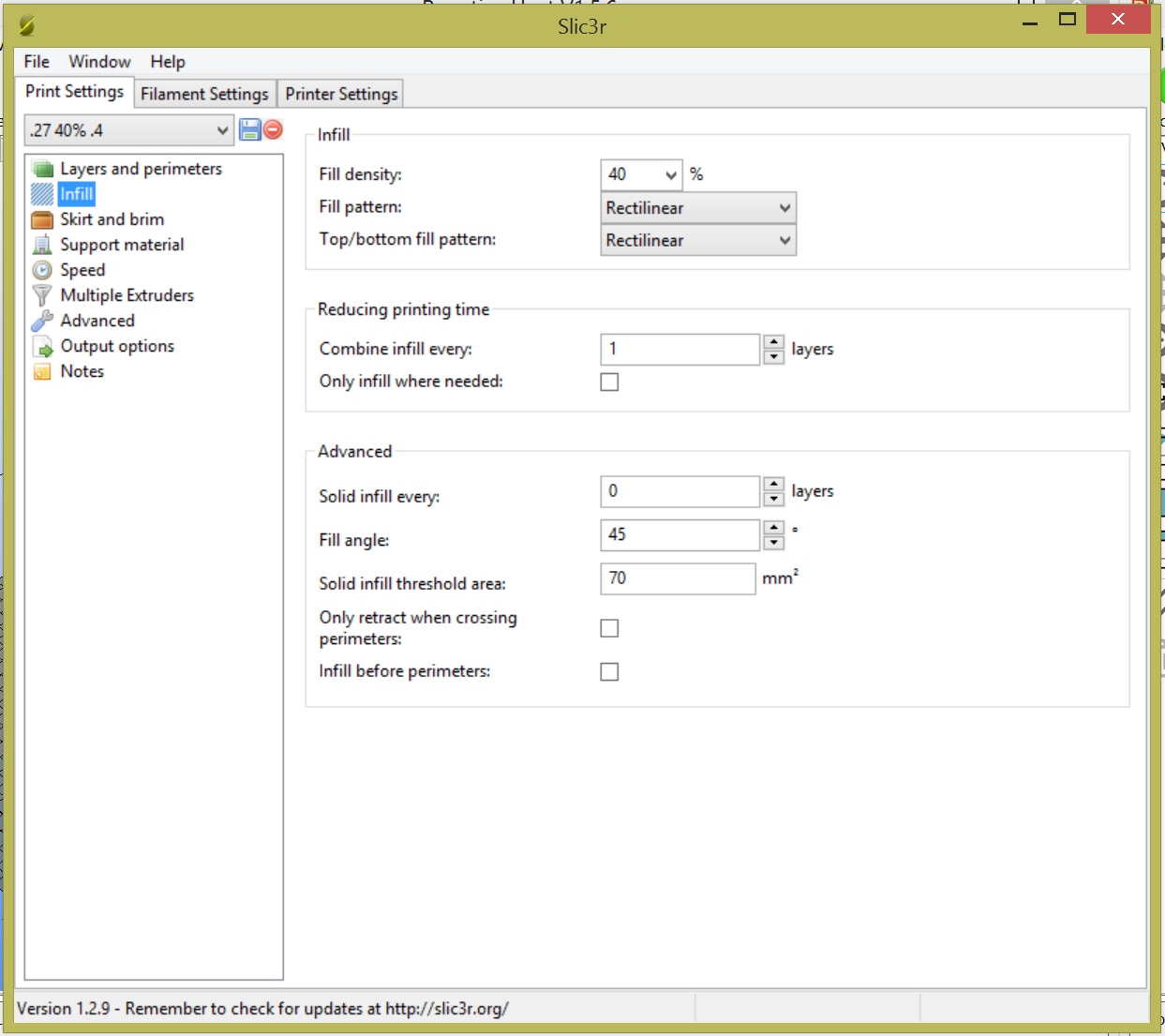

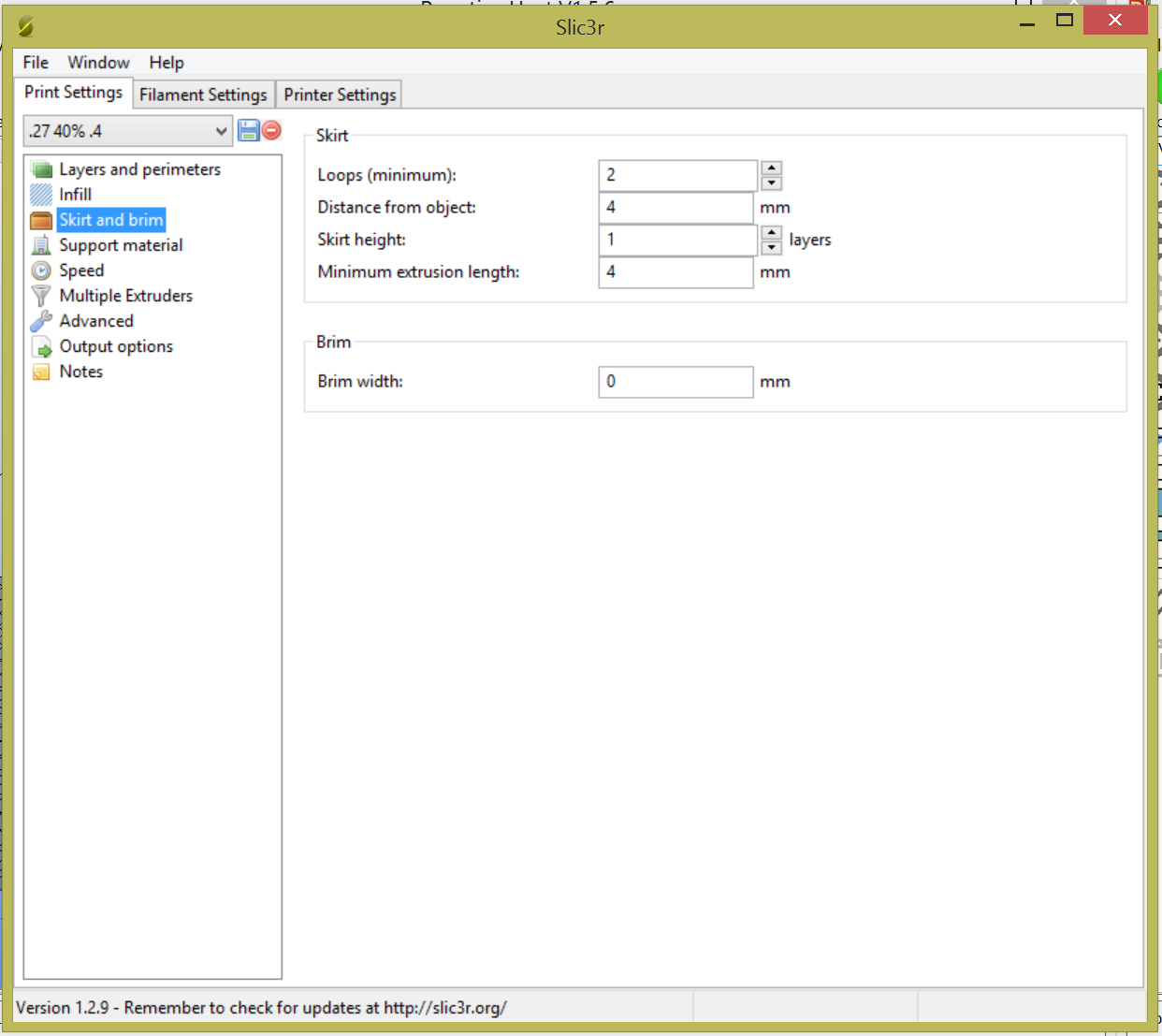

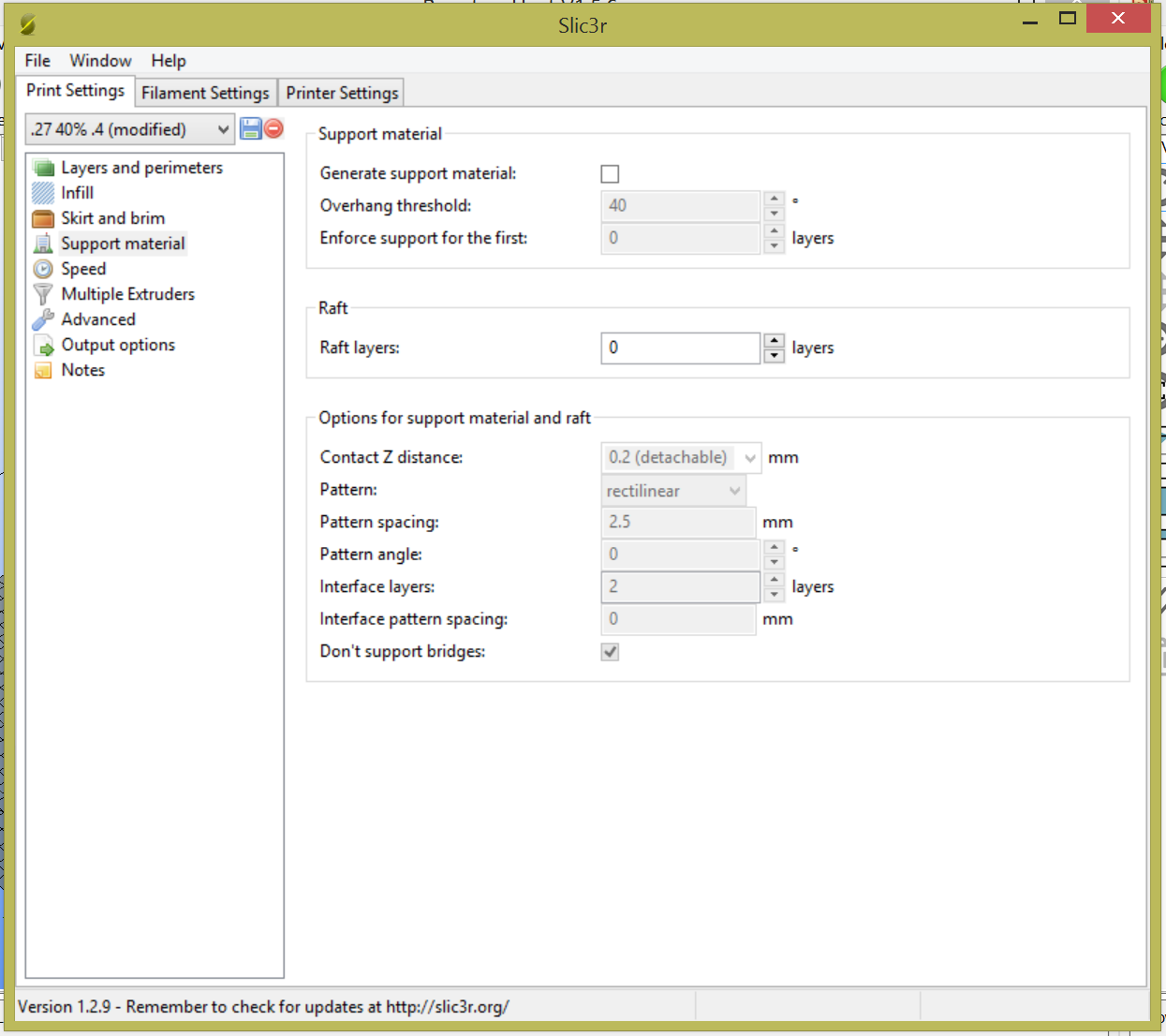

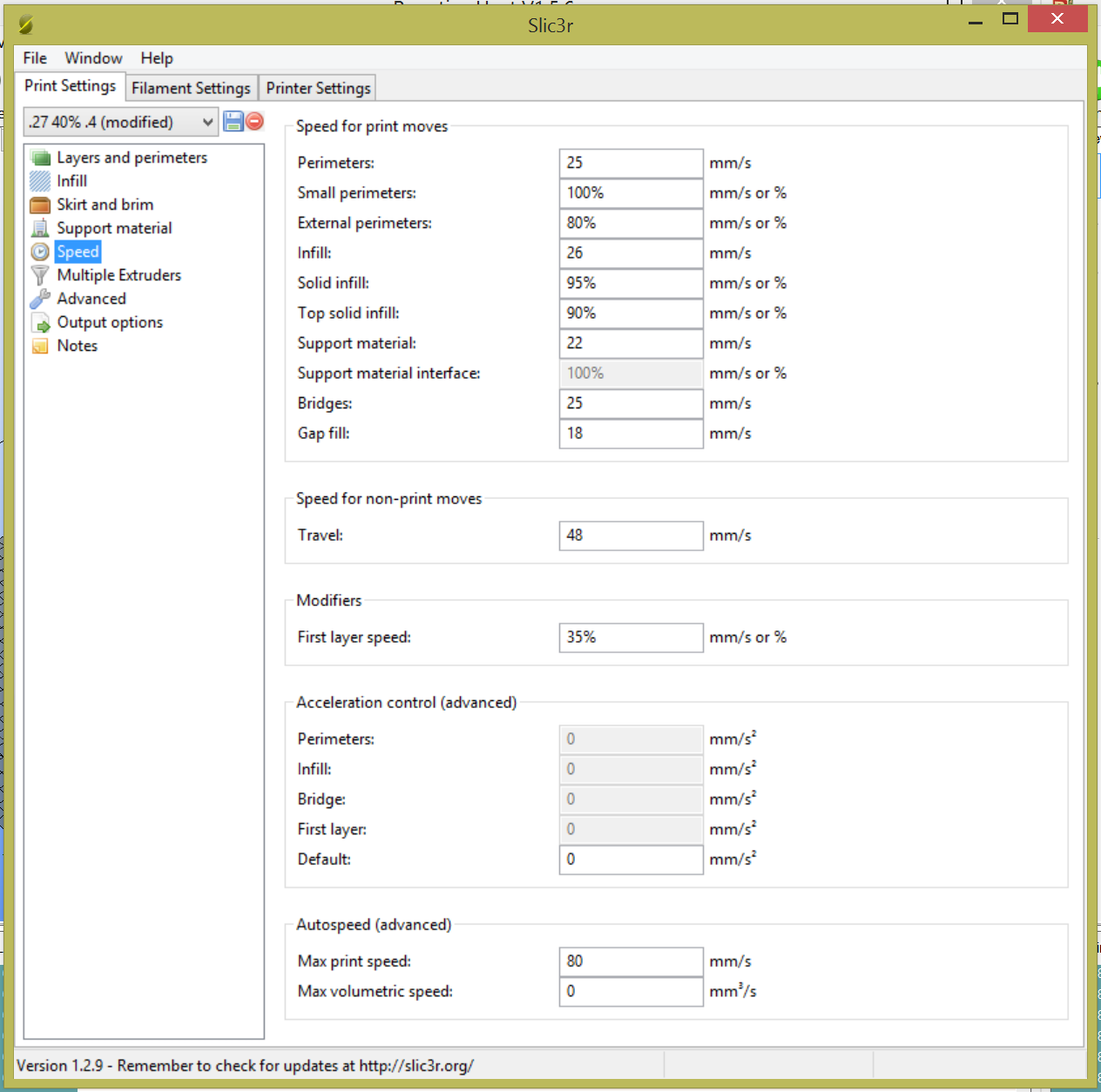

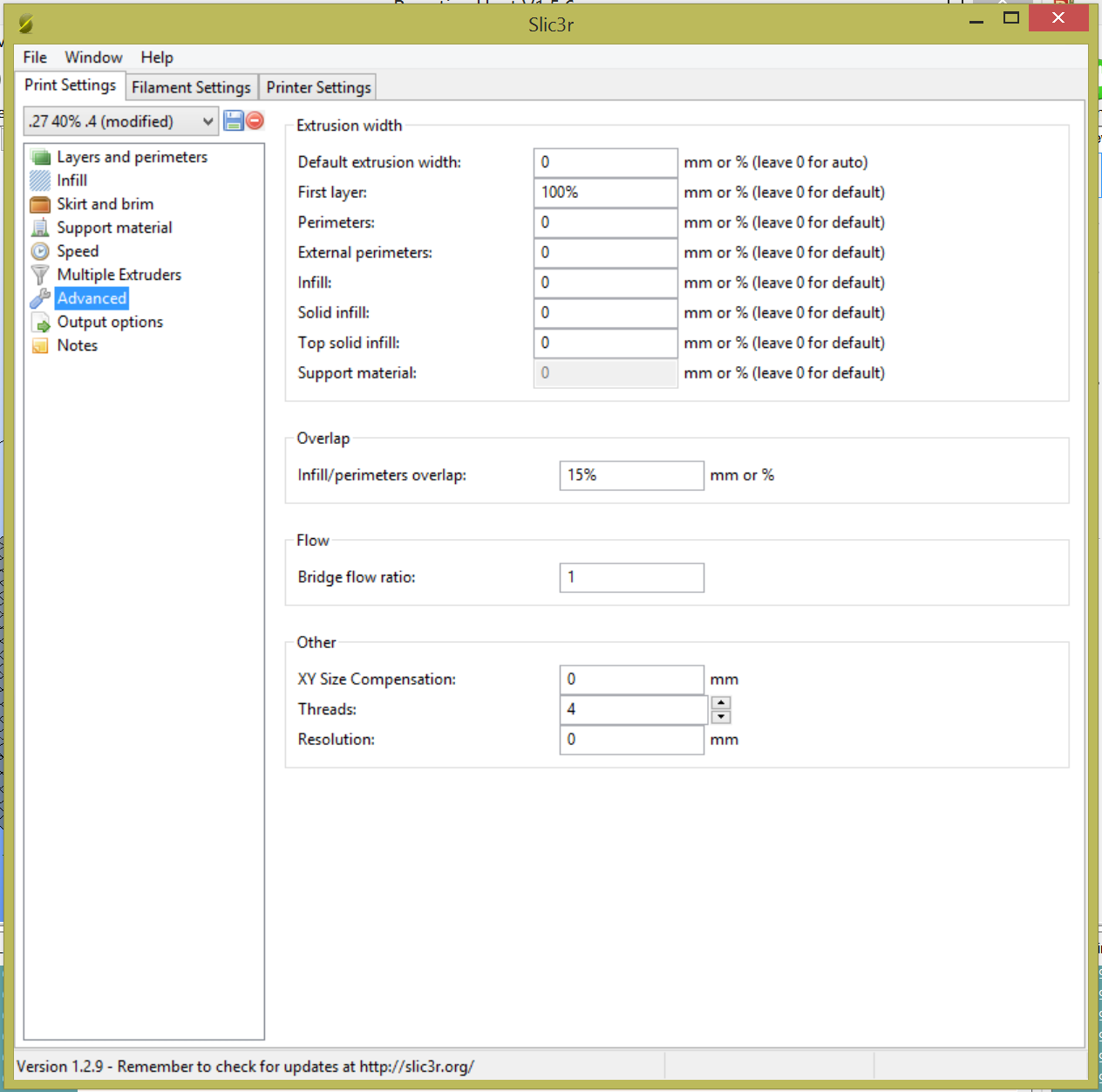

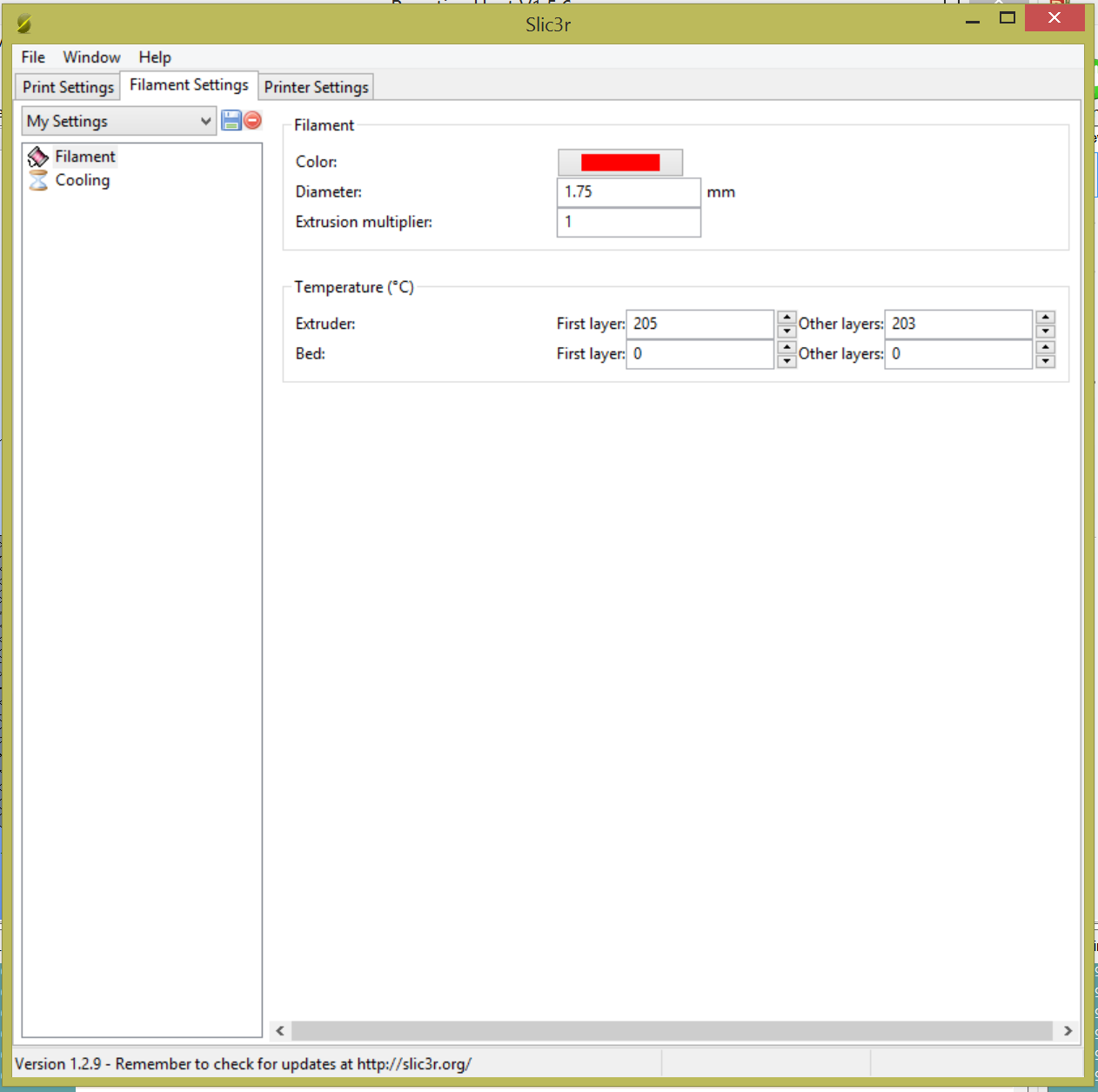

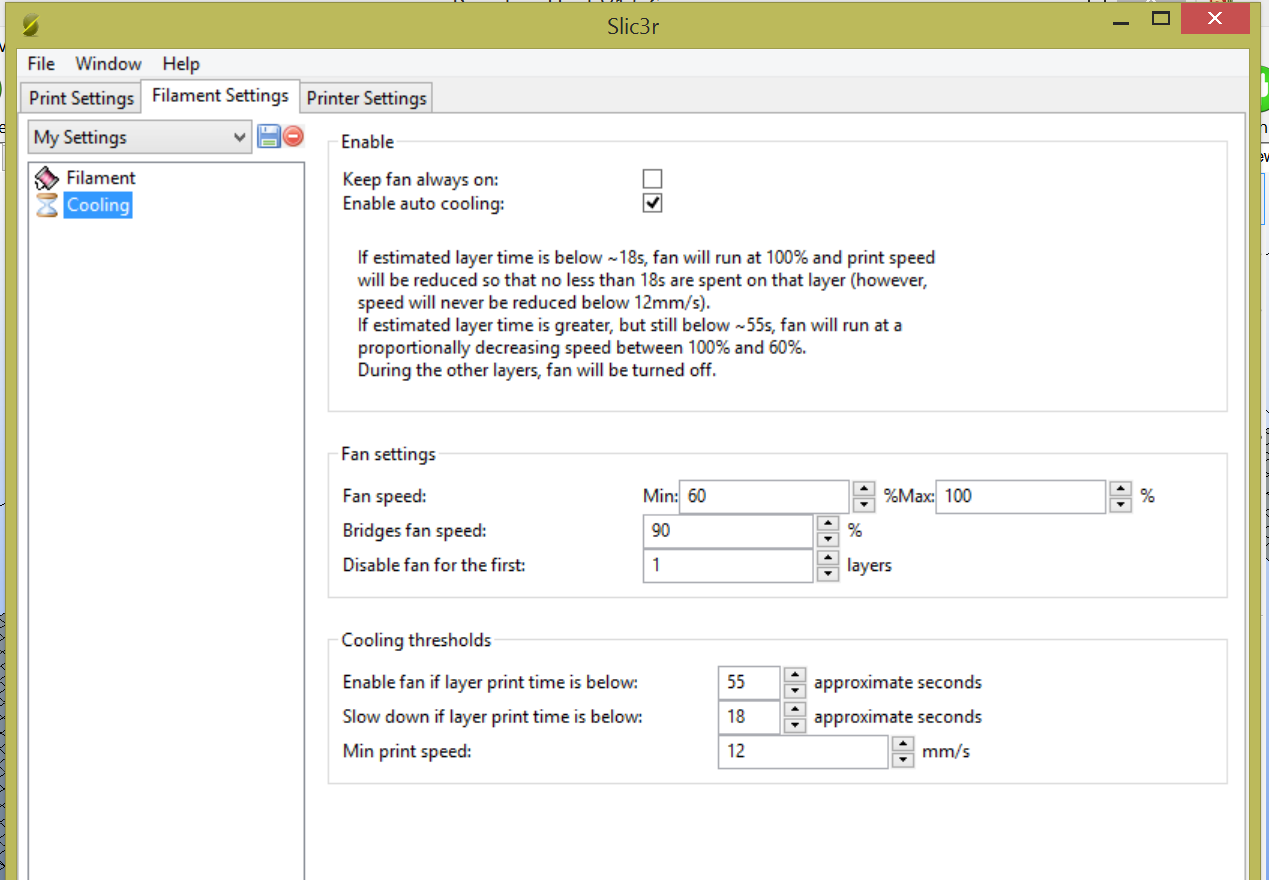

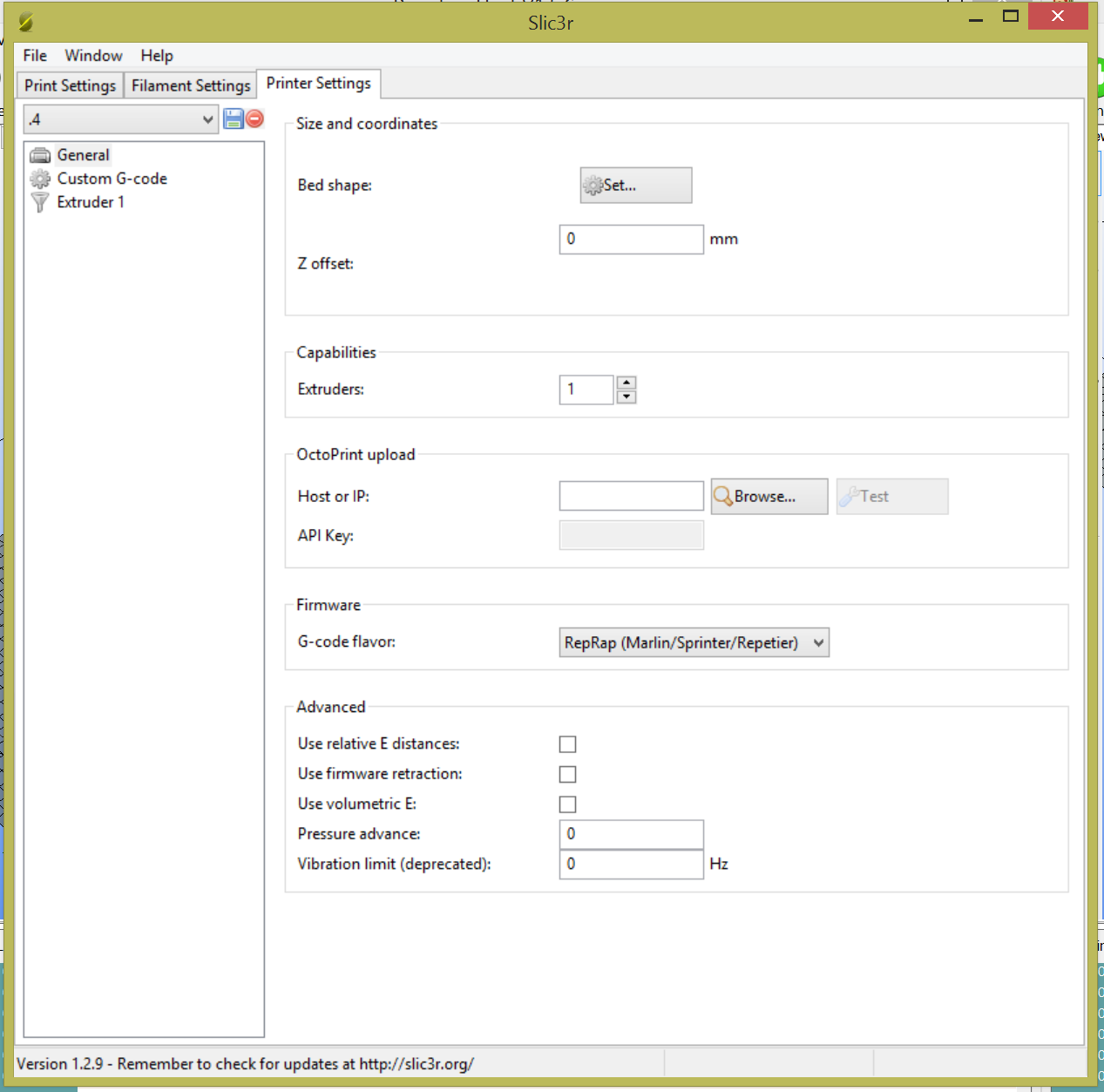

Recommended beginning slic3r settings.¶

Test file just in case.