Conduit, Rails, Tubes, Pipes…¶

The Rails¶

This CNC runs on inexpensive thin walled galvanized steel conduit found in 23.5mm, 25mm, 25.4mm Outside Dimension (OD). Stainless steel tubing (wall thickness approx. .049″-.065″) is a good upgrade that increases rigidity and accuracy.

In the US ¾″ thin walled EMT fits the 23.5mm parts, ¾″ refers to the Inside Dimension. The price for conduit is about $8 US for the ~20′ needed. Stainless Starts at about $3.50 US/foot

Recommended Starting Size¶

Very large builds are possible, if the outer rails are supported along the span. The smaller the machine the more rigid it will be, the faster you can push it. I recommend starting with a footprint of no larger than 24″ X 24″ Outer Dimensions with a 2-3″ usable height.

Cut Calculator¶

Check out the Calculator

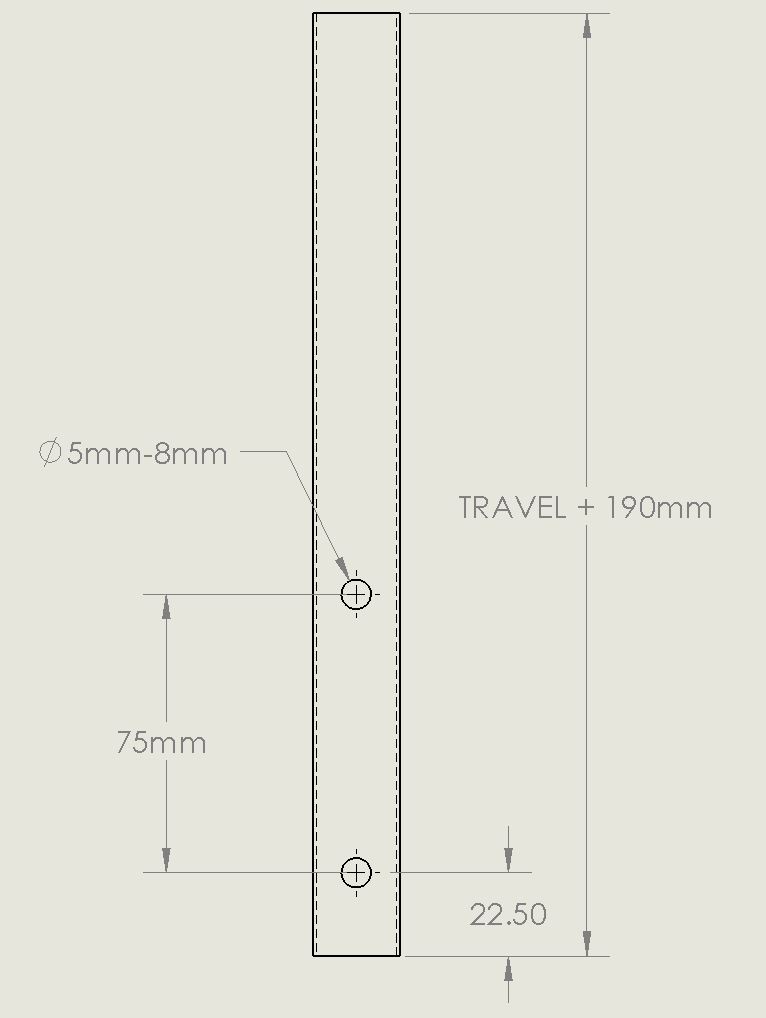

Z axis¶

Z Rails should have 5-8mm holes drilled 22.5mm from the bottom and one 75mm above that. The diameter can be anywhere between 5mm and 8mm to allow for the tool mount and a little non-perfect alignment when drilling a tube.

- If you bought super thick rails and your nut traps don’t fit your rails’ thickness well, GeoDave made a nice parametric part here.

Sharp Edges¶

File or sand down the inner and outer sharp edges left after cutting! Sharp edges make assembly difficult and can damage your wires. I have one of these and It was worth every penny (only works on US standard EMT).

Sample Cut list¶

3 Rails X = Usable Width +264mm (10.4in)

3 Rails Y = Usable Depth +264mm (10.4in)

2 Z Rails = Usable Height + 190mm (7.5in)

4 Legs = Usable Height – 13mm (.5in)

1 Lead Screw (T8) or Allthread = Usable Height + 76mm (3in)

Table will be 6.5mm (.25in) longer in each axis direction. (30in X rail will need a 30.25in table in the X direction).